Product Search

Quickly find the product you need.

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Contact Us

Telephone:15680139111(Mr. Sun)

Telephone:13320881016(ms. liang)

Telephone:15066253625(Mr. Gao)

Address: High-tech Industrial Park, Jiangyou City, Sichuan Province

How to clean a boiler?

Release time:

2022-12-06

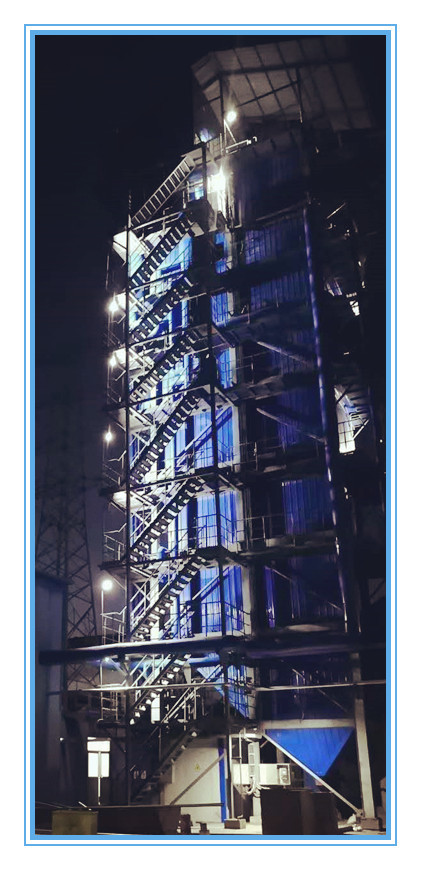

The boiler adopts the structure of suspending

The boiler adopts the structure of suspending all membrane wall light tube, which can expand freely, has light weight and good thermal insulation performance. The boiler is conveniently arranged for various capacities and fuels. Auxiliary heating surfaces such as economizer and air preheater are supplied modularized to reduce the installation workload on site. Membrane walls and coils are designed in a standardized manner to reduce supply cycles.

First, cleaning methods

1. Machine wash

Mechanical cleaning is manual cleaning using a high-pressure water gun. In general, scale, blockage or surface deposits inside the boiler will be removed

2, chemical cleaning

Chemical cleaning is pickling. Only certified manufacturers and environmental protection units with certified certificates can carry out cleaning. Rust, scale and oil in the boiler system are cleaned and dispersed by adding chemical cleaning agents to restore the clean metal surface.

Second, cleaning procedures

1. Know the situation

Understand the structure, materials and heat transfer of boiler cleaning. There are dozens of boilers on the market, each with a different heat exchange method, structure and material, and each structure and material requires a different cleaning method. Cleaning personnel analyze and test different areas, water quality and scale, prepare different chemical cleaning agents for different materials and scale, and put forward scientific and reasonable cleaning programs.

2. Descaling and cleaning

According to the ratio of boiler cleaning and descaling, a set of descaling cleaning agent is added to the circulating water of the cleaning tank to determine the cleaning cycle time and the added cleaning dose. scale

3. Clean with water

After cleaning the equipment and connecting the boiler, cycle the water for 10 minutes to check the system status and whether there is leakage at the same time

4, peel anti-corrosion cleaning

Add an appropriate amount of surface remover and sustained-release agent to the circulating water of the cleaning tank, and carry out a 20-minute cycle cleaning to separate the scale from the parts to be cleaned. Scale is removed during cleaning so that the cleaner does not corrode the parts to be cleaned. The surface is treated with corrosion protection.

5, passivation coating treatment

Passivation coating agent is added to passivate the boiler cleaning system to prevent corrosion and formation of new rust in pipes and components.

Third, the common methods of boiler transformation are as follows:

1, boiler flue gas waste heat recovery

Industrial boiler flue gas emission temperature is generally high, above 180℃, not only pollute the environment, but also waste valuable flue gas waste heat resources. The use of heat pipe heat transfer technology can effectively recover the waste heat resources of the polluted flue gas, which can be used to preheat the boiler combustion air, preheat the boiler feed water or directly produce hot water.

2, boiler coal delivery equipment maintenance

At present, all floor boilers use raw coal, and most of them are positive rotary chain grate boilers. On the grate, it will block the boiler's air intake and affect combustion. The bucket coal feed is changed to stratified coal feed, and the raw coal and the final coal are filtered by the grate through the gravity filter. From bottom to top. Promote air intake, improve combustion conditions, increase coal. According to the carbon content of the slag, the coal saving rate can reach 5%~20%. According to the furnace condition before renovation, the worse the furnace condition with different energy-saving effect, the higher the effect. The project investment is small, the energy saving effect is high, and the recovery speed is fast.

Key words:

Related News

According to the decision of The State Council on amending

2024-02-05

The integration of production and education helps double carbon

In order to promote the technological progress of enterprises

2023-12-23